The audiophile lacquer cut at half tempo

Half-speed mastering is nothing new: it was used as early as 1949, recordings were still made on wax discs back then. In 1970, the half-speed technique had to be used again for quadrophonic records in order to properly cut the modulated signal for the rear channels at 30kHz. Even today it still makes sense to go for half-speed mastering: Especially for program material with a lot of high end and transparent sound, half-speed mastering is a means to achieve additional sonic finesse, offering a possibility of refining high-quality audiophile products.

The fundamental principle

The half-speed technique can be applied when cutting a lacquer master that is intended for industrial vinyl record manufacturing. During the process, both the source (tape or computer) and the cutting lathe run at half tempo. This way, the limits of what is possible in analog technology can be pushed even further. The music is pitched down by one octave, so making the lacquer masters in half speed takes twice as long as the actual program duration. The finished vinyl record looks just like any standard vinyl record and when played back, it reproduces the program material at the correct pitch. However, the process has certain sonic advantages.

What are the considerations behind this principle?

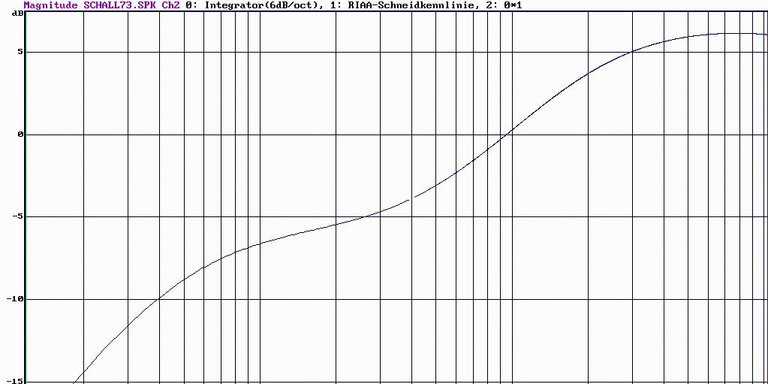

Small children are able to perceive frequencies between 20 and ca. 20.000 Hz. However, with increasing age that range becomes smaller. A modern cutting stylus is able to cover the entire range, but, as with human beings, problems start in the high end. Mechanical forces on the cutting mechanism are enormous when cutting high frequencies, which can lead to limitations. Reducing the pitch by half during the cutting process moves the frequency spectrum to the unproblematic range of 10 to ca. 10.000 Hz. This has a beneficial impact on the apparatus' exposure to mechanical forces.

To illustrate this effect, imagine a fast-paced car ride on a winding mountain road. Driving at half the speed reduces stress on the material as well as on the driver. The danger of screeching tires or scratching against the rockface would be drastically reduced. Similar to that, the cutting stylus can modulate a winding groove more precise, which renders it less prone to losses at half speed.

Sonic advantages of half-speed mastering

Half-speed mastering makes a clear improvement in high-frequency reproduction on a vinyl record. The frequency range is extended, while distortions are reduced. The technique has been used in the past, to protect the cutter head from wear or because extremely high frequencies needed to be cut for quadrophonic playback. The first of these two points is still relevant today: Electronic music with a lot of high end can be cut without too many trade-offs due to less force on the cutter head.